Die cutting

We provide tailored solutions of precision custom die-cutting, each aimed at improving your manufacturing processes whilst reducing your product costs. 0ur converting team offers expert design, prototype and manufacturing advice, working with you to find the most suitable solution for your application.

Any conceivable shape or size

We can die cut all possible sizes up to 320 mm of width and 320 mm of length per piece.

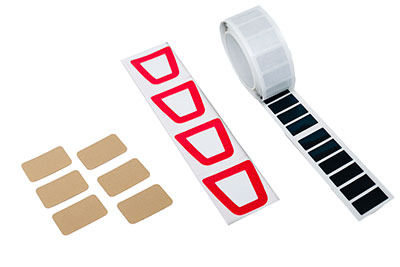

Individual pieces, on rolls or sheets

Butt-Cut: a continuous line of rectangular/square die-cut pieces with no spacing between the pieces supplied on an interliner

Individual die-cut shapes on a roll: a line of individually separated die-cut shapes supplied on an interliner in roll form

Chopped Pieces: die-cut pieces supplied individually not in roll form

Small- or full-scale production

Flatbed die-cutting makes it possible to produce small, medium or large series with moderate tooling costs. It also accommodates thicker materials than rotary methods allow.

Very complementary to flatbed die-cutting, rotary die-cutting is using precision engraved steel cylinders and is more appropriate for more complex parts and higher production rates on large series.

Expertise

Our converting team offers expert design, prototype and manufacturing advice, working with you to find the most suitable solution for your application.

Technology

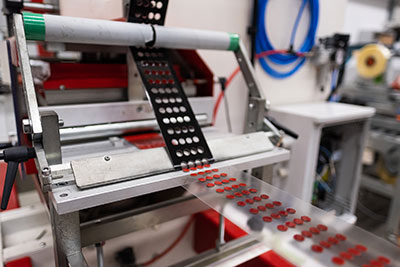

Rotary die cutting

Rotary die cutting uses a cylindrical mould on a rotary press. Rolls of material are driven by this press while the mould rotates. As a result of this die cuts are created, the material is perforated or is cut into smaller pieces. The moulds that are used during this process can be engraved or adjustable. Engraved moulds are more tolerant and are made of one solid cylinder.

Flatbed die cutting

During the process of flatbed die cutting the press will exert a pressure of minimum 10 tons. Flatbed die cutting is recommended for smaller quantities and thicker material. The moulds which are used are also less expensive than cylindrical moulds. Steel knives are held in place by plywood or steel braces. These moulds are ideal for short runs where the cost of a rotary tool is too high.